Press Release Description

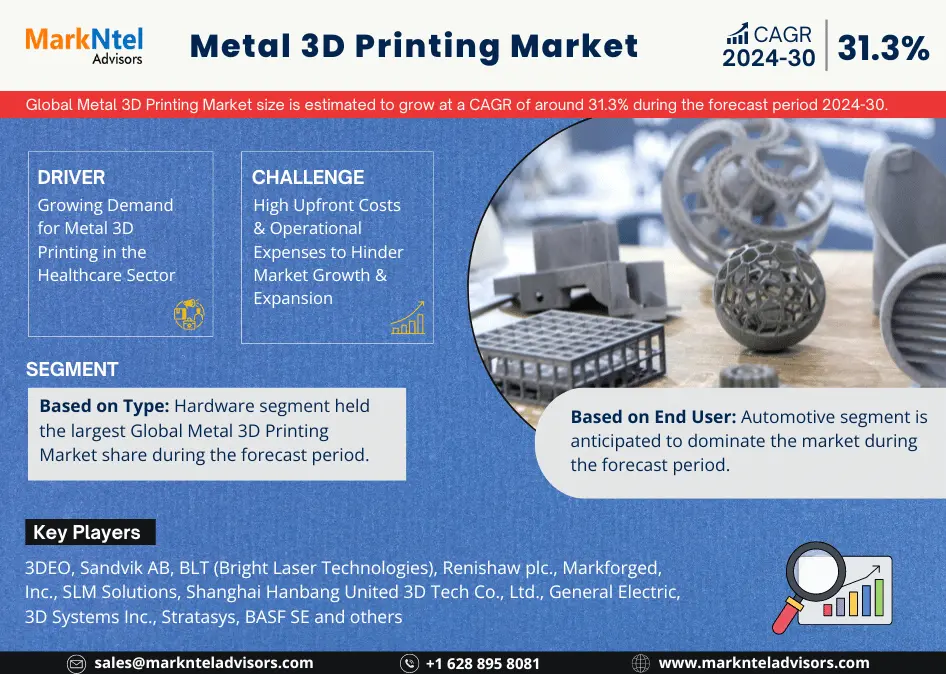

Global Metal 3D Printing Market to Grow at a CAGR of Around 31.3% During 2024-30

The Global Metal 3D Printing Market is anticipated to grow at a CAGR of about 31.3% during the forecast period of 2024-30, cites MarkNtel Advisors in the recent research report. he rising inclination of the various industry verticals to streamline their production process & enhance their capabilities is resulting in the increasing adoption of metal 3D printing globally. Industrial units across the globe follow a highly complex product development process that involves various steps. Therefore, the industrial units are automating their manufacturing process by integrating various technologies. The key industries globally are using metal 3D printing technology to streamline the production of their products such as aircraft, medical implants, automobiles, etc., amplifying the Global Metal 3D Printing Market.

Moreover, enterprises & organizations across the globe are shifting toward sustainability and are increasingly looking out for solutions that help reduce industrial waste. Therefore, these industries are using metal 3D printing technologies since these innovative technologies are based on additive layer manufacturing that eliminates wastage. Hence, the transition of the companies towards their sustainable & environmentally friendly targets is enhancing the adoption of metal 3D printing, enlarging its market size.

Furthermore, governments across the globe are encouraging the adoption of smart & innovative technologies within their production units to streamline their business operation and ensure the consistent supply of the products in the market. The official governing authorities are increasingly providing subsidies & incentives to the industries to adopt these latest technologies. As a result, the demand for Global Metal 3D Printing would continue to increase even in the foreseen years, further states the research report, “Global Metal 3D Printing Market Analysis, 2024.”

Global Metal 3D Printing Market Segmentation Analysis

Hardware Segment Holds a Major Market Share

Based on the type, the market is further bifurcated into hardware, software, and services. The hardware segment has been dominating the market in line with the one-time high cost associated with systems. The complex systems require high-quality, expensive raw materials to withstand and effectively work for longer lifecycles. These printers incorporate advanced technologies and precision components to enable the deposition of metal powders or wire feedstock with high accuracy. The significant upfront cost associated with purchasing metal 3D printing hardware contributes to its increased share in the market.

Moreover, governments across the region are investing heavily to improve & create advanced metal 3D printing systems. This would help in providing a conducive business environment for the major market players, amplifying market growth.

Asia-Pacific Leads the Global Metal 3D Printing Market

Geographically, the market is bifurcated into North America, South America, Europe, The Middle East & Africa & Asia-Pacific. Among them, Asia-Pacific holds a dominant market share of the Global Metal 3D Printing market. The countries in the region have low labor costs owing to which these countries are becoming industrial hubs. Several foreign companies are investing in these countries to establish their production units. These production units use metal 3D printing technology to ease their production process and enhance their capabilities. Therefore, the establishment of manufacturing units in the Asia-Pacific countries is amplifying the Global Metal 3D Printing market. Furthermore, the academic institutions, research centers & governing authorities in the region are encouraging the usage of metal 3D printing since it helps in improving the quality of the products. Thus, the rising government encouragement would continue to amplify the need for metal 3D printing in Asia-Pacific.

Competitive Landscape

With strategic initiatives such as mergers, collaborations, and acquisitions, the leading market companies, including 3DEO, Sandvik AB, BLT (Bright Laser Technologies), Renishaw Plc., Markforged Inc., SLM Solution, Shanghai Hanbang United 3D Tech Co., Ltd., General Electric, 3D Systems Inc., Stratasys, BASF SE, AMLD3D Limited, Wipro Enterprises Pvt. Ltd., Proto Labs, Inc., Hoganas AB, and others, are looking forward to strengthening their market positions.

Key Questions Answered in the Research Report

- What are the industry’s overall statistics or estimates (Overview, Size- By Value, Forecast Numbers, Segmentation, Shares)?

- What are the trends influencing the current scenario of the market?

- What key factors would propel and impede the industry across the regions?

- How has the industry been evolving in terms of geography & product adoption?

- How has the competition been shaping up across various regions?

- How have buying behavior, customer inclination, and expectations from product manufacturers been evolving during 2019-30?

- Who are the key competitors, and what strategic partnerships or ventures are they coming up with to stay afloat during the projected time frame?

We offer flexible licensing options to cater to varying organizational needs. Choose the pricing pack that best suits your requirements:

Buy NowNeed Assistance?

WRITE AN EMAIL

sales@marknteladvisors.comCustomization Offered

100% Safe & Secure

Strongest encryption on the website to make your purchase safe and secure